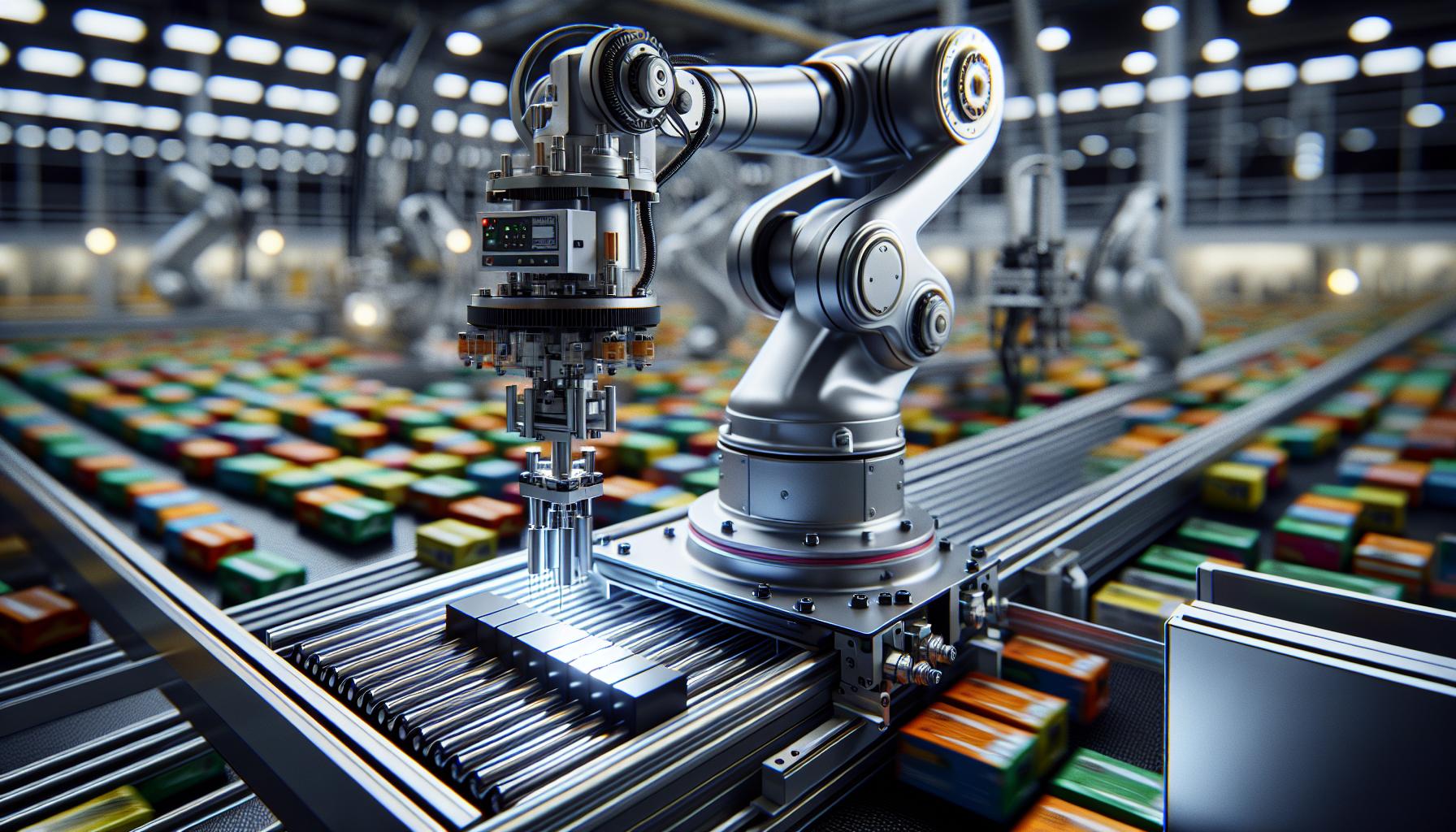

Color-sensing robots have revolutionized numerous industries by bringing enhanced precision and automation to tasks that once required human visual inspection. These sophisticated machines use advanced sensors to detect and differentiate various colors, making them invaluable tools in modern manufacturing and quality control processes.

From sorting products on assembly lines to ensuring consistent paint application in automotive manufacturing, color-sensing robots have proven their worth across diverse applications. They excel in environments where accurate color detection is crucial for maintaining product quality and operational efficiency. The technology’s ability to operate 24/7 while maintaining consistent accuracy has made it an attractive solution for businesses looking to streamline their processes and reduce human error.

In What Industries or Applications Would a Robot With Color Sensors Be Useful

Color sensing technology enables robots to detect and analyze different wavelengths of light reflected from objects, transforming visual data into digital signals for processing.

How Color Sensors Work

Color sensors in robotics operate through photoelectric detection systems that measure light wavelengths. These sensors emit white light onto objects then analyze the reflected light through RGB (Red, Green, Blue) filtering components. The reflected light intensity creates specific electrical signals that correspond to distinct color values, allowing robots to differentiate between colors with precision levels of up to 16.7 million distinct hues.

Key Components and Capabilities

The essential components of robotic color sensing systems include:

- Light Sources: LED arrays that emit consistent white light

- Photodetectors: Silicon-based sensors capturing reflected light frequencies

- RGB Filters: Optical components separating light into primary colors

- Signal Processors: Microcontrollers converting light data into digital values

- Interface Systems: Communication modules transmitting color data

- Detection Range: 350-750 nanometer wavelength spectrum coverage

- Processing Speed: Color recognition in 25-50 microseconds

- Accuracy Rates: 99.9% color matching precision

- Environmental Adaptation: Automatic calibration for varying light conditions

| Component Type | Response Time | Accuracy Rate |

|---|---|---|

| Basic Sensors | 50 µs | 95% |

| Industrial Grade | 35 µs | 98% |

| Premium Systems | 25 µs | 99.9% |

Manufacturing and Quality Control Applications

Color-sensing robots enhance manufacturing processes through automated visual inspection and quality control. These systems integrate seamlessly into production lines to perform precise color-based tasks with 99.9% accuracy.

Product Sorting and Classification

Color sensors enable robots to sort products by specific color parameters on high-speed production lines. These systems categorize items based on subtle color variations at rates of 1,000+ units per hour with real-time processing capabilities. Manufacturing facilities use color-sensing robots to:

- Sort packaged goods by brand colors

- Separate raw materials based on color grades

- Classify components for assembly line distribution

- Organize finished products by color specifications

- Verify color coding on electrical components

- Monitoring paint finish uniformity in automotive production

- Detecting discoloration in food products

- Identifying surface blemishes in textile manufacturing

- Verifying color matching in cosmetics production

- Inspecting print quality in packaging materials

| Quality Control Metric | Color Sensor Performance |

|---|---|

| Detection Range | 350-750 nanometers |

| Processing Speed | 25-50 microseconds |

| Color Match Accuracy | Up to 99.9% |

| Inspection Rate | 1,000+ units/hour |

| Minimum Color Variation Detection | 0.1 nanometers |

Food and Beverage Industry Uses

Color-sensing robots enhance quality control and safety standards in food and beverage production facilities. These automated systems perform precise color analysis at speeds of up to 100 items per minute with 99.9% accuracy.

Food Processing and Grading

Color-sensing robots evaluate food products based on ripeness stages color variations:

- Sort fruits by ripeness levels using RGB wavelength detection

- Remove discolored items from production lines at rates of 2,000 pieces per hour

- Grade meat products based on USDA color standards within 0.1% variance

- Detect browning or oxidation in fresh produce using 350-750nm wavelength sensors

- Identify foreign objects on conveyor belts through color pattern recognition

- Inspect label colors against Pantone standards with 99.9% accuracy

- Verify expiration date stamps using contrast detection algorithms

- Monitor seal integrity through color pattern analysis

- Check fill levels in transparent containers using light transmission sensors

- Compare packaging artwork to digital templates at 50 units per minute

- Detect printing defects as small as 0.5mm on product packaging

- Validate barcode color contrast ratios for optimal scanning

| Color Sensing Performance Metrics | Value |

|---|---|

| Inspection Speed | 100 items/minute |

| Color Accuracy | 99.9% |

| Defect Detection Size | 0.5mm |

| Wavelength Range | 350-750nm |

| Processing Rate | 2,000 pieces/hour |

Automotive Industry Applications

Color-sensing robots revolutionize automotive manufacturing through automated visual inspection systems that ensure consistent quality across vehicle production. These robots perform precise color matching operations with an accuracy rate of 99.8% while processing up to 60 components per minute.

Paint Quality Control

Color-sensing robots monitor paint application consistency throughout the vehicle coating process. These systems detect color variations as small as 0.1 Delta-E units across different body panels using spectrophotometric analysis at 16 measurement points per square inch. The robots scan freshly painted surfaces for:

- Identifying paint thickness irregularities between 0.5-3.0 millimeters

- Detecting orange peel effects in clear coat applications

- Measuring gloss levels ranging from 20-95 GU (Gloss Units)

- Evaluating color matching across multiple body panels

- Spotting surface defects including runs drips or sags

Assembly Line Verification

Assembly line robots equipped with color sensors validate component placement accuracy through:

| Verification Task | Processing Speed | Accuracy Rate |

|---|---|---|

| Wire color coding | 120 parts/minute | 99.9% |

| Interior trim matching | 45 parts/minute | 99.7% |

| Light assembly inspection | 80 parts/minute | 99.8% |

| Dashboard component verification | 60 parts/minute | 99.6% |

- Color-coded electrical connectors for proper installation

- Interior trim piece color consistency

- Correct positioning of colored indicators on dashboard components

- Proper assembly of taillight lens colors

- Paint match verification between assembled components

Medical and Pharmaceutical Settings

Color-sensing robots enhance accuracy in medical diagnostics and pharmaceutical processing through automated visual inspection systems. These robots operate with precision in controlled environments, maintaining strict quality control standards essential for healthcare applications.

Medicine Authentication

Color-sensing robots authenticate pharmaceutical products by detecting subtle variations in pill colors tablet coatings with 99.8% accuracy. The systems scan up to 200 pills per minute comparing medication colors against verified reference databases. Advanced sensors detect counterfeit medications by identifying inconsistencies in color pigmentation surface texture gloss levels. Integrated systems catalog color data for each batch enabling complete traceability throughout the supply chain.

- Sorting blood collection tubes by their standardized cap colors (lavender for EDTA red for serum)

- Monitoring chemical reactions through precise color change detection

- Analyzing urine test strip results by measuring RGB values

- Categorizing biological specimens based on staining protocols

- Tracking sample progression through color-coded workflow stages

| Laboratory Application | Processing Speed | Accuracy Rate |

|---|---|---|

| Blood Tube Sorting | 150 tubes/hour | 99.9% |

| Chemical Analysis | 120 samples/hour | 99.7% |

| Urine Strip Reading | 100 strips/hour | 99.8% |

| Specimen Classification | 90 samples/hour | 99.6% |

Agriculture and Produce Management

Color-sensing robots transform agricultural operations through automated monitoring systems that enhance crop management efficiency. These systems integrate advanced color detection technology with precision farming techniques to optimize harvest timing and reduce waste.

Crop Ripeness Detection

Color-sensing robots analyze fruit ripeness by detecting specific wavelength patterns with 98% accuracy. The sensors measure subtle color variations in produce like tomatoes strawberries apples at rates of 120 items per minute. Advanced algorithms process RGB values to determine optimal harvest windows based on standardized ripeness charts established by agricultural institutions. These systems detect chlorophyll levels through near-infrared sensing identifying peak nutrient content in leafy greens kale spinach lettuce.

- Selective picking based on color thresholds

- Multi-spectral imaging for disease detection

- Color-based sorting during collection

- Real-time quality grading through RGB analysis

| Harvesting Performance Metrics | Value |

|---|---|

| Color Detection Accuracy | 98% |

| Processing Speed | 120/min |

| Harvest Rate | 8,000/hr |

| Color Distinction Capability | 16M |

| Selection Accuracy | 95% |

Textile and Fashion Industry

Color-sensing robots transform textile manufacturing through automated color analysis systems that maintain consistency in fabric production. These advanced systems process up to 150 fabric samples per hour with a color matching accuracy of 99.7%.

Fabric Color Matching

Color-sensing robots analyze fabric color properties using spectrophotometric technology to ensure batch-to-batch consistency. The systems measure:

- Detect color variations as small as 0.2 Delta-E units across fabric rolls

- Compare fabric samples against digital color standards stored in databases

- Process multiple fabric types including cotton, polyester, silk within 3 seconds

- Analyze color fastness under different lighting conditions (D65, A, F11)

- Match thread colors for seamless garment assembly

| Fabric Analysis Metrics | Performance Data |

|---|---|

| Processing Speed | 150 samples/hour |

| Color Matching Accuracy | 99.7% |

| Minimum Detectable Variation | 0.2 Delta-E |

| Color Database Capacity | 10,000+ standards |

| Analysis Time per Sample | 3 seconds |

- Monitor dye bath concentrations in real-time with 0.1% precision

- Track color development during dyeing cycles every 30 seconds

- Identify inconsistencies in dye penetration across fabric surfaces

- Evaluate washing fastness through automated color measurement

- Generate digital reports for quality documentation with timestamp data

| Dyeing Process Metrics | Performance Values |

|---|---|

| Dye Bath Monitoring | Every 30 seconds |

| Color Consistency | ±0.5% variance |

| Sample Analysis Rate | 200 points/minute |

| Documentation Speed | Real-time logging |

| Quality Verification | 99.5% accuracy |

Color-sensing robots have revolutionized numerous industries by bringing unprecedented precision and efficiency to tasks that once relied on human visual inspection. From manufacturing and automotive production to healthcare and agriculture these intelligent machines continue to push the boundaries of automation and quality control.

Their ability to detect subtle color variations with remarkable accuracy has made them indispensable in modern industrial processes. As technology advances these sophisticated systems will likely find even more applications across different sectors driving innovation and setting new standards for precision and productivity.

The integration of color-sensing robots represents a significant step forward in industrial automation demonstrating how specialized technological solutions can transform traditional processes while delivering consistent reliable results.